According to the customer's needs, the development test of the instrument panel assembly includes the instrument panel body, glove box, glove box, air outlet, electronic display screen, steering column and other parts:

Test Item

Test Item

KTL / kwt test of instrument panel assembly

Threaded fastener test

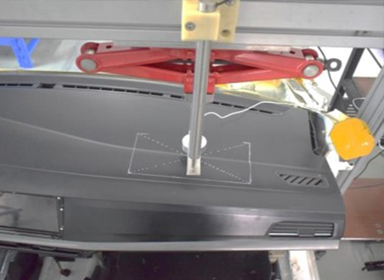

Static stiffness test of instrument panel

assembly

Screw in and out test of threaded connection

Instrument panel assembly airbag cover abuse

test

Rolling test of cockpit assembly

Vibration test of instrument panel assembly

Steering column cover Durability / abuse test

Installation test of metal chuck / clip on

instrument panel

Glove box stiffness / abuse / durability test

Subjective evaluation and installation test of

instrument panel assembly

Durability test of glove box

Dynamic stiffness test of instrument panel

assembly

Abuse test of glove box assembly

Vibration test of steering column cover

Panel / strip disassembly test

Durability test of steering column cover

Seal plate assembly and disassembly test

Misuse test ofsteering column cover

At present, Huiyue Test has established a series of instrument panel development test capabilities, including raw material test, component test, total successful capability test and vehicle instrument panel test capabilities, in addition to airbag point explosion. The models involved include Audi Q5, Q3, Lavida, Passat, kodiaq, karoq, tayron, tharu, Yeti, polo, etc.

Case sharing:

Rolling test of cockpit assembly GB 11552, EP 84 080.04 Screw in and out test of threaded connection EP 84 110.04

Instrument panel assembly airbag cover abuse test EP 84 100.70 Misuse test ofsteering column cover EP 84 129.70